|

Making

Home-Style Molasses is an excerpt from ďCapín Dellís StoriesĒ written by

William Odell Spain.

One of the things that the

old folks did was to make molasses from the cane that they grew in their

fields. We sopped it up with hot Mama-made biscuits, and rich cowís cream

poured on it Ė yum, yum.

Most of the time, the whole community was involved in

the process. It took all day and several different steps to get to the

barrel it was stored in. There were two cane mills on the Island. Mr.

John Carawan had the first one at his home in Lowland, and later on, Mr.

Herbert Pollard, Mr. Joseph Roberson, and Mr. Edmond Jones owned one

together in Hobucken. It was on the School House Road on Mr. Herbert

Pollardís land, Mr. Joseph Robertson was the cooker. His son,

Bert, and

Mary Alice Spain both told me they had had their fingers burned many times

sampling the molasses. (They lived close to where it was going on.)

People set aside a portion of their land to

grow the cane. It looked a lot like corn; it was about the same size in

height and width, but the tassel (or seedpod) was different. When it was

ripe and ready, the first thing they had to do was strip all the leaves

from it while it was still standing in the field. Then it was cut and

hauled to the boiling site, where the top was cut off. This is where

other people got involved in the process; others came just to see what was

going on.

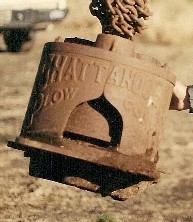

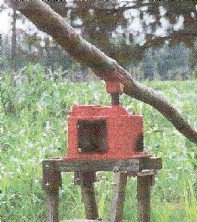

The stalks were then ready

to run through the cane mill. This was quite an operation. The cane mill

was a set of rollers set close together in a frame with gears on top and a

pan with a spout underneath. One of the shafts went on up fairly high and

had another bracket on it. This was where a pole attached, about twelve

feet in length running off clear of the mill. The mule that hauled cane

in the cart to the site was unhooked, and the pole from the cane mill was

hooked behind him in about the same place as the plow had been.

(Sometimes there was a special mule there, because not all mules

understood what they were supposed to do.)

The mule walked around in a

circle, turning the mill as he went. There was a rope hooked to his

bridle bit that went to where the pole hooked to the machine. It was

tight enough to keep him from trying to get away; his instinct was to move

away from it. There was a person working under the pole, feeding the cane

into the mill and making sure not to put too much into it because the mule

would stop if it got too hard to pull. He also had to make sure the

bucket was in the right place to catch the liquid as it was squeezed out

of the stalks. This was a pea green sweet juice, and watery; the flies

were attracted to it.

Close by was a big pan

called the boiler pan. It was about seven feet long, three feet wide, and

six inches deep, and would hold seventy-five to a hundred gallons. It had

partitions in it that reached from one side almost to the other, and make

the juice zigzag as it went down the pan. You needed plenty of long

firewood under the pan, and lots of manpower. First, a hot fire was built

under it from one end to the other, and then the juice was brought from

the bucket under the mill. On the way, it was poured through big cloths

to filter out any trash that had gotten into it. Pouring the juice into

the pan was a six-to- seven-hour job; as the juice began to boil, it had

to be constantly skimmed to remove the cane residue that rises to the

top. Small paddles were used to keep it moving until it was "ready", as

they called it. Mary Alice said her folks made her her own little paddle

so she could help.

There was great skill

involved in knowing when it was the right time to stop cooking: if all

the water wasn't removed, it would sour and be no good; if it was

overcooked, it would have a burnt taste and turn to sugar.

I had the pleasure of going

over to Aurora and sitting with Mr. Charles Carawan and his wife Mabel

recently. They were both borne in Lowland; he is the son of Mr. John Carawan who had the cane mill at his house from 1928-30. Charles tells me

that the family that brought the cane in operated the mill to get the

juice, and his father cooked it for them. He was paid a portion of the

molasses. One year, they had plenty of molasses and one of the barrels

soured, so they had to get rid of it. Mr. John had about a dozen hogs in

a pen and decided to feed it to them. Not knowing what was about to

happen, Charles said his daddy put some of the molasses out and came back

into the house. In a little while, the hogs became noisy, which was

unusual. They were squealing real loud, so he went out to the pen. Some

of the hogs were setting just like a dog, shaking their heads and

squealing; some were lying down and squealing, and Charles said some of

them were actually smiling. The juice had fermented and the hogs were

drunk.

Another story was told to me

by Mrs. Joannie Spain. She said that one day, a bunch of children were

playing when the word came out that they were making molasses through the

swamp, a distance of about a mile. The children went and got cold

biscuits and went through there, and sopped the molasses up as they made

it. It was just like a Camp Meeting day, she said.

I have tried to trace down

these machines, and had about gave up on finding either one of them. Then

I had some pretty good luck. I was in Charlie's Restaurant and Bill

Potter, his wife Wayne Ray and their son, Grady, were at another table.

They stopped by at our table on their way out. In the conversation, I

asked Bill what he knew about making molasses. He said he knew quite a

bit and that he had Mr. Edgar Barnettís machine. It was the machine that

was here in Hobucken and Mr. Edgar Barnett got it; he lived up the Springs

Creek Road between Lowland and Hobucken, and made molasses with it. (I

don't think he made anymore than his own use.) After Mr. Edgar got old

enough that he couldn't get his driverís license renewed, he went around

on his tractor until that gave out. Bill Potter from Lowland saw the

problem and went to stopping by on his way out and picking Mr. Edgar up so

he could get whatever they needed.

One day, Mr.

Edgar told Bill

that he could have the old mill and pan, so Bill got it. Bill told me he

planned to grow cane and make some molasses from it, but it never happened.

The old mill was put in a building and kept inside until the storms of

1999 took the building down.

There are

still a lot of these mills around; they are turned by an engine of some

kind. Iím told they still make molasses in the mountains, too, and that

itís a tourist attraction in some places.

|

![]()